Cement bulker trailer are specifically engineered for bulk powder transportation, with wide applications in cement factories, construction sites, and material distribution centers. Featuring a sealed cylindrical tank, the bulker trailer enable efficient and clean transfer of cement, fly ash, and other powdered materials without leakage.

The bulker trailer tank body is constructed from Q345 high strength carbon steel, boasting a tensile strength of over 510MPa. Through a combination of circumferential reinforcement rings and longitudinal support beams, the cement bulker forms a pressure-resistant tank structure that prevents deformation under full load.

Even when transporting 40 tons of cement powder (equivalent to the capacity of 250 standard cement bags), the tank body maintains stability without bulging. The static pressure test of the cement bulker trailer reaches 130% of the designed pressure, and the cement bulker vibration resistance on rough rural roads in dynamic tests surpasses industry standards by 25%.

Cement Bulker Trailer for Sale in Rwanda

Cement Bulker Trailer for Sale in Rwanda

Cement Bulker Trailer for Sale in Rwanda

Cement Bulker Trailer for Sale in Rwanda

Cement Bulker Trailer for Sale in Rwanda

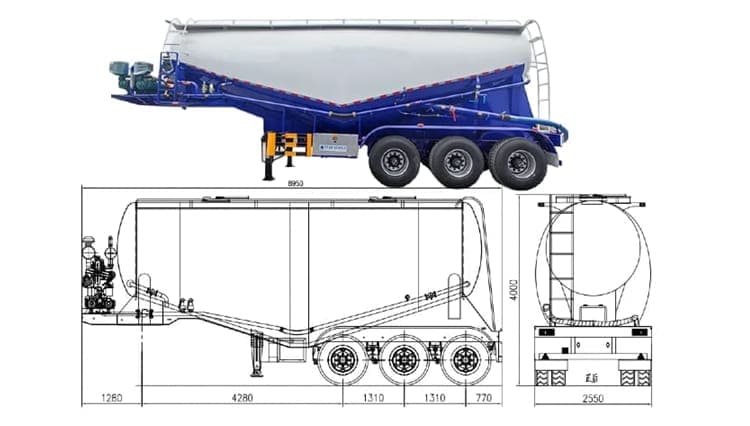

Dimension: 8950mm * 2550mm *4000mm

Tanker body material: 5mm high strength wear resistance steel

Payload: 40 ton

Axles: 3 axles

Tire: 12 units

Compressor: 12m³ double cylinder air compressor

Diesel Engine: WEICHAI Brand

Compressor: BOHAI

Suspension: Heavy-duty mechanical suspension

Landing gear: JOST

Cement Bulker Trailer for Sale in Rwanda

The bulker trailer tank interior is polished with a food grade anti-stick coating, reducing cement residue by 45% and enabling thorough discharge. Equipped with adjustable discharge valves (one set at the front and one at the rear of the tank), it can adapt to different unloading speeds required by small construction sites and large-scale projects. For long distance transportation, an optional temperature insulation layer can be added to prevent moisture absorption and caking of cement in Rwanda’s humid climate.

The cement bulker tank frame adopts integral welding technology, with the main beam using an H-shaped cross section design , connected by 18 transverse support beams to form a rigid load-bearing framework. Critical welds are completed by robotic automatic welding with a weld leg height of 7mm. No cracks or incomplete fusion are detected via ultrasonic flaw detection, ensuring the frame’s service life reaches 12 years / 280,000 kilometers.

The cement bulker trailer for sale in Rwanda is divided into three independent modules: the tank module, the pneumatic discharge module, and the control module, with universal interfaces between each module. This design cuts maintenance and part-replacement time by 55% and allows for custom add-ons like cement level sensors and high-pressure tank cleaning systems based on customer needs.

The cement bulker trailer tank surface undergoes shot blasting derusting , followed by two coats of epoxy zinc-rich primer—achieving a salt spray resistance of 1200 hours without rust. After primer curing, a polyurethane topcoat with UV resistance is applied. This coating not only maintains gloss in Rwanda’s strong sunlight but also resists corrosion from cement bulker powder and occasional rainwater.

This dual coating system forms a tight protective film, preventing paint peeling and limiting rust coverage to less than 3%. The cement bulker fully withstands Rwanda’s harsh conditions of high temperature , high humidity, and dusty rural roads, significantly prolonging the trailer’s service life.

LED side marker lights with reflective strips are installed along the entire length of the cement bulker trailer, with a visibility range of up to 350 meters in dim light or fog. The cement bulker trailer tires have a tread depth, enhancing grip by 32% on gravel roads and muddy construction sites common in Rwanda.

Before shipment, the cement bulker trailer receives multi-layer comprehensive protection to ensure the intact delivery of the cement bulker:

Paste EPE shock-absorbing cushioning cotton on the inner wall of the shipping container to reduce collision impact on the cement bulker trailer; fill the gap between the protruding parts of the cement bulker trailer (such as discharge pipes and level sensors of the cement bulker) and the container with high-elasticity foam filling blocks to eliminate shaking space of the cement bulker. Finally, attach a waterproof moisture-proof film to the inner surface of the container to isolate external rainwater and humid air, fully adapting to Rwanda’s coastal transportation and inland storage environments for the cement bulker trailer.